Lapping

Lapping the valve is the final process in ensuring a full circumferential fit between the valve and the seat. Although the valve appears to have good contact all the way around as visualized with machinist’s dye, the dye is thick enough that this is not necessarily true.

Lapping, which is the use if a progressively finer grit abrasive paste between the valve face and the seat, will ensure the best possible mating surfaces.

Lapping compound is available in a variety of grits. Generally, the process begins with a coarse paste (60-120 grit) and completes with a fine paste (280 - 400 grit).

The valve face is spread with the lapping paste.

The valve is then installed in place, and repeatedly oscillated back and forth. This causes removal of metal from the valve face.

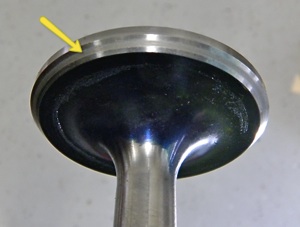

The valve is inspected and lapped repeatedly until there is evidence of contact - a very fine line that is dull grey - all the way around the valve face.

The valve may be oscillated by several methods. Traditionally, a wooden stick with a suction cup at one end is used. The cup adheres to the top f the valve, and the stick is rolled between the hands much like primitive fire starting. Periodically,the valve is removed to apply more paste.

As this can be very time consuming, I favor a mechanized valve lapper.

The valve and seat are now both correctly prepared and the valve can be finally installed and used.